About Egg Tray Production Line Cost

- By Little Dianne

- •

- 08 May, 2019

- •

egg tray production line

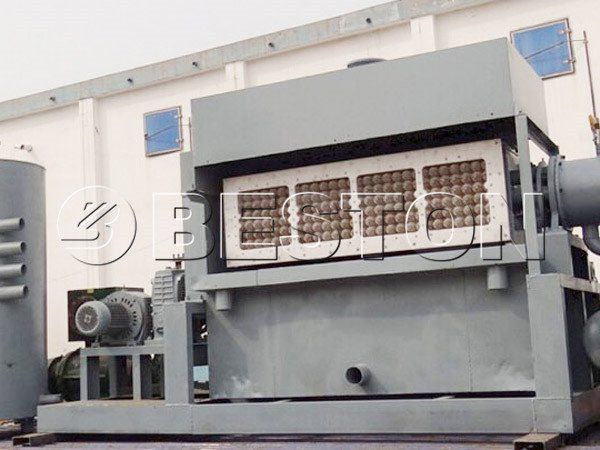

Egg-tray production-line cost requires the entire production line in association with making egg trays which are made up of 3 working systems which include the pulping system, the forming system and also the drying system. The egg tray production line

can easily create large batches of egg trays which include the 2000pcs, a 3000pcs, a 4000pcs, a 5000pcs, a 6000pcs as well as a 7000pcs every hour.

So that you can determine the egg tray production line cost you can find 3 systems involved including:

1. The Pulping System

This is actually the initial stage of producing egg trays, which is a vital factor that many buyers overlook when considering the important points from the egg-tray production line. In this particular phase the raw recycled materials are coupled with water. This technique generates a pulp or slurry that is then dried to make egg trays. This method consists of a pulping machine, a hydra-pulper, the mixer, slurry pump along with various pipes. Click here to know more: https://eggtraymachines.net/.

2. The Molding System

This technique is considered the most essential section of the producing egg trays. This method is really what displays the exact capacity to do with the egg tray making machine, the speed in which the egg trays are designed, the size and style and types that happen to be molded combined with the overall drying process. This system makes used of vacuum absorption and negative pressure to change the pulp or slurry which was created in the first portion of the system into either apple trays, egg cartons to egg trays. From here it employs a positive pressure in order to transport the trays in to the final drying phase. The ingredients that define this technique incorporate a compressor, air tank, steam/ vacuum tanks separator, the molding machine and the mold. The Egg Tray Production Line cost will likely be low, which leads to higher returns.

3. The Drying System

Prospective investors who wants to verify the information about the egg tray machine of egg trays should pay close attention in relation to the ultimate stage which include drying and after that packaging. It is of importance to ensure that this technique runs smoothly. The most effective drying processes will result can lead to a decline in loss related to poorly-formed trays. This method involves drying the semi-finished wet products with the use of hot pressing and pressure.

Any organization owner or entrepreneur that invests within the production lines to help make egg trays would like to ensure they purchase one of those machines coming from a professional and reputable manufacturer. The greater egg-tray production lines are easy to run and operate and have the ability to meet up to the needs of consumers. These machines use spoilt or used egg trays to make new trays. To obtain the highest productivity and efficiency it is important to choose the best machine.

So that you can determine the egg tray production line cost you can find 3 systems involved including:

1. The Pulping System

This is actually the initial stage of producing egg trays, which is a vital factor that many buyers overlook when considering the important points from the egg-tray production line. In this particular phase the raw recycled materials are coupled with water. This technique generates a pulp or slurry that is then dried to make egg trays. This method consists of a pulping machine, a hydra-pulper, the mixer, slurry pump along with various pipes. Click here to know more: https://eggtraymachines.net/.

2. The Molding System

This technique is considered the most essential section of the producing egg trays. This method is really what displays the exact capacity to do with the egg tray making machine, the speed in which the egg trays are designed, the size and style and types that happen to be molded combined with the overall drying process. This system makes used of vacuum absorption and negative pressure to change the pulp or slurry which was created in the first portion of the system into either apple trays, egg cartons to egg trays. From here it employs a positive pressure in order to transport the trays in to the final drying phase. The ingredients that define this technique incorporate a compressor, air tank, steam/ vacuum tanks separator, the molding machine and the mold. The Egg Tray Production Line cost will likely be low, which leads to higher returns.

3. The Drying System

Prospective investors who wants to verify the information about the egg tray machine of egg trays should pay close attention in relation to the ultimate stage which include drying and after that packaging. It is of importance to ensure that this technique runs smoothly. The most effective drying processes will result can lead to a decline in loss related to poorly-formed trays. This method involves drying the semi-finished wet products with the use of hot pressing and pressure.

Any organization owner or entrepreneur that invests within the production lines to help make egg trays would like to ensure they purchase one of those machines coming from a professional and reputable manufacturer. The greater egg-tray production lines are easy to run and operate and have the ability to meet up to the needs of consumers. These machines use spoilt or used egg trays to make new trays. To obtain the highest productivity and efficiency it is important to choose the best machine.